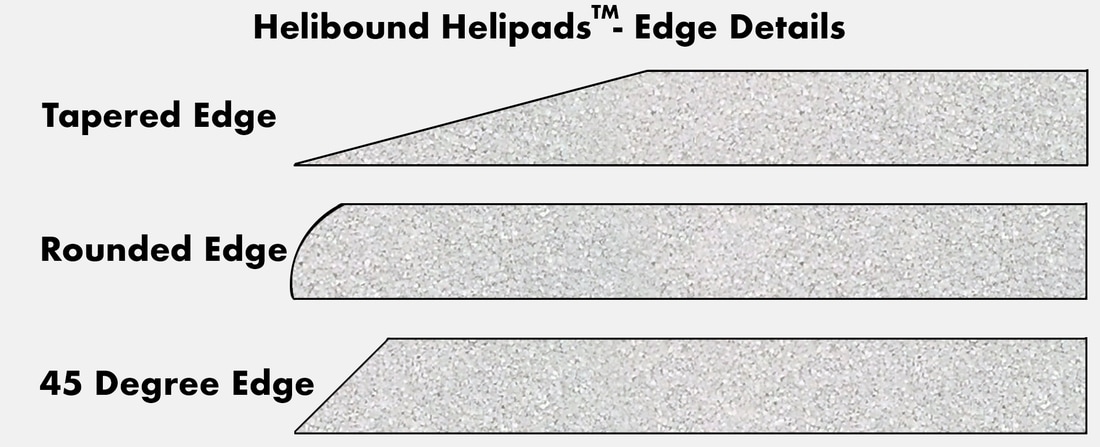

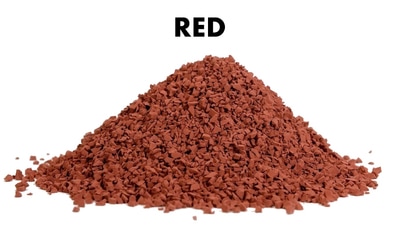

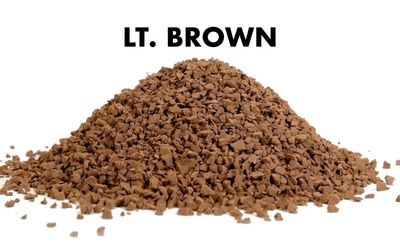

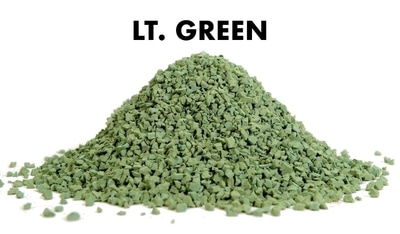

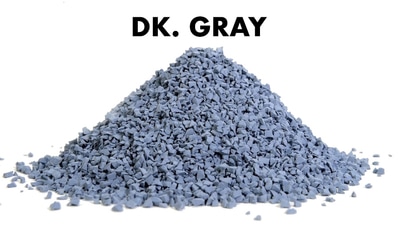

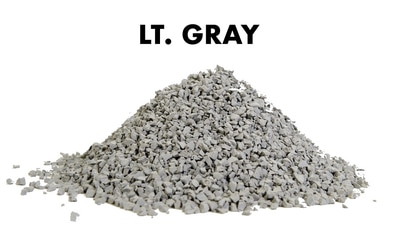

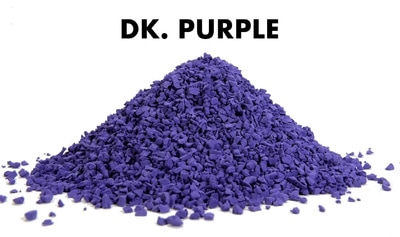

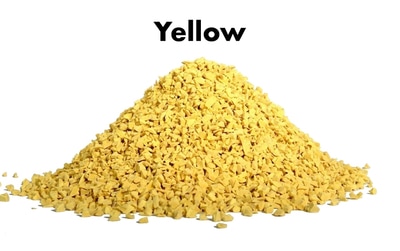

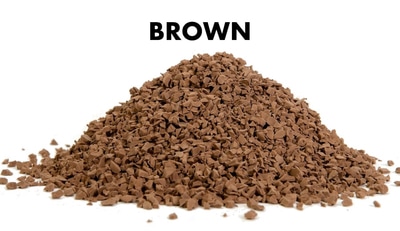

"Non-Slip rubber durability made to last and

to fit custom to any order.”

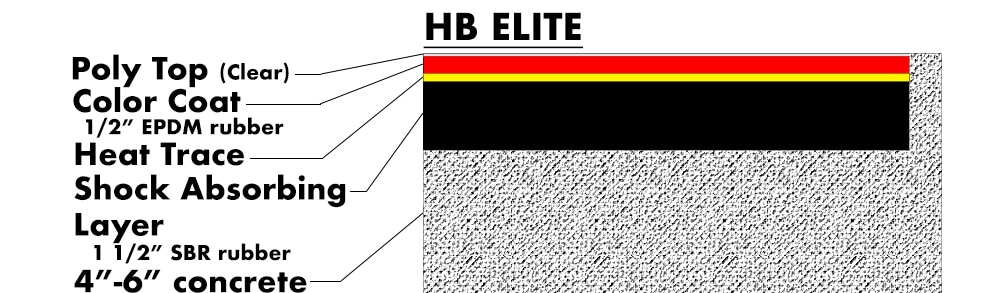

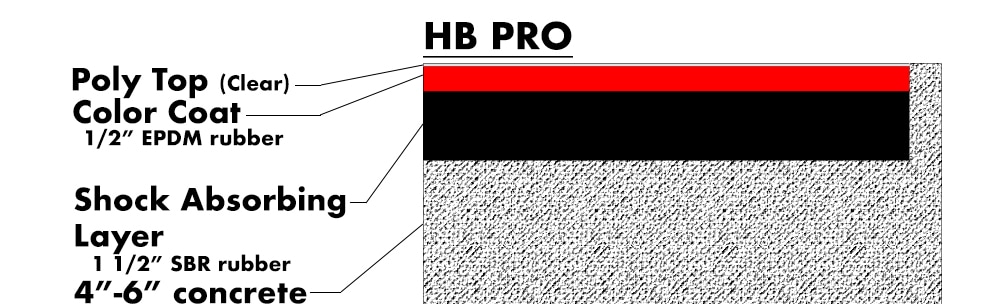

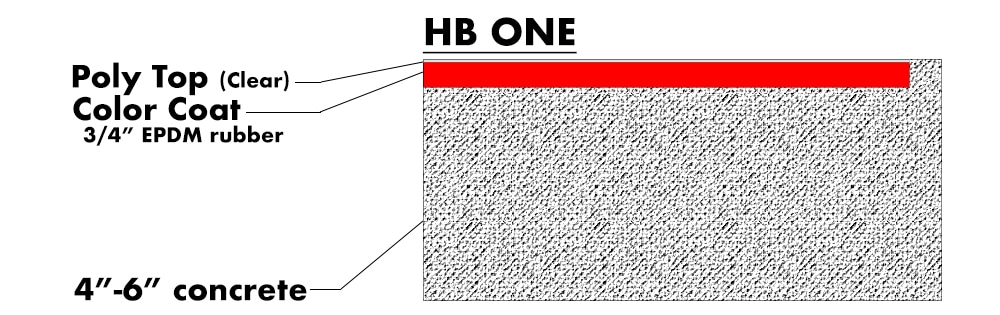

Helibound's helipad surface treatment systems are superior. This rubberized system is poured and we have the ability to install it seamless as one solid piece. Helibound's military grade helipad is ideal for situations where a permanent helipad is required of the mission.

| heli_hb_elite_specifications.docx | |

| File Size: | 71 kb |

| File Type: | docx |

| helibound_5-year_warranty.pdf | |

| File Size: | 61 kb |

| File Type: | |

| heli_hb_pro_specifications.docx | |

| File Size: | 71 kb |

| File Type: | docx |

| helibound_5-year_warranty.pdf | |

| File Size: | 61 kb |

| File Type: | |

| heli_hb_one_specifications.docx | |

| File Size: | 71 kb |

| File Type: | docx |

| helibound_5-year_warranty.pdf | |

| File Size: | 61 kb |

| File Type: | |

There are many advantages to using a rubberized surface on helipads, here are just a few.

- *Dry Static Coefficient of Friction (ASTM D2047): 1.0.

- *Wet Static Coefficient of Friction (ASTM D2047): 0.9.

- *Dry Skid Resistance (ASTM E303): 89.

- *Wet Skid Resistance (ASTM E303): 57.

- *Reduces the shock load experienced by the helicopter upon touchdown.

- *Attenuate rotor vibration while the helicopter is idling down or warming up.

- *Reduces the level of noise present both inside and outside the helicopter.

- *Provides a surface capable of attenuating the impact of tools, aircraft parts, and munitions in order to eliminate or at least reduce the possibility of damage, misfiring, and sparking.

- *Reduces substantially the cost of maintenance necessitated by damage caused by shocks to the helicopter.

- *Eliminates cracking and eroding of the landing pad, which saves the end user substantially on maintenance and/ or replacement.

- *HELIBOUND creates a surface that can withstand the rigorous punishment of cargo containers, helicopters, and heavy equipment all the while maintaining an aesthetic touch with endless graphic capabilities!

- *Longevity of all markings